NORSK DYREMAT AS – sustainability strategy 2022–2030

Main projects

Upgrade the factory in Sirevåg

Saving energy

New products

Communicating sustainability

GOAL

AMBITION

Reduce emissions and use more of the animal (and other sources of protein).

We pledge to address climate and environmental concerns through specific targets and measures in how we operate (better utilisation of raw materials, new raw materials and less waste). How we manage general operations (office buildings, transport and purchasing). We will also focus on the use of protein sources in a holistic perspective.

DIVERSITY AND INCLUSION

Generate long-term value creation, have satisfied customers (and dogs) and be an attractive employer.

ABOUT — NORSK DYREMAT AS

A business based on the circular economy

Norsk Dyremat AS was founded on the idea of producing healthy and nutritious animal food using meat products are not used in products for human consumption.

Around 20 years ago, 80–90 per cent of these raw materials were destroyed. These days, an ever-growing portion of these raw materials are refined by various companies – this is a journey which we at Norsk Dyremat are very proud to have been part of. Our goal is to receive and refine all the leftover materials from the production of food for human consumption. Through innovation and collaboration, we are looking for new ways to create added value and enable us to get as much as possible out of the ingredients that we have.

Norsk Dyremat AS is a subsidiary of Nortura, which is Norway’s leading supplier of meat materials. This ensures that we have stable access to very high quality raw materials, which is our main competitive advantage. Nortura works with other parties and helps us to find new sources of protein that would otherwise be lost, ensuring that we will be able to meet the need for protein in the future.

ABOUT — NORSK DYREMAT AS

Our value chain

ABOUT — NORSK DYREMAT AS

Our story

Facts

RESPONSIBLE PRODUCTION

PROTECT JOBS AND IMPROVE SKILLS

HSE 40-hour course. Autoclave course.

VALUE CREATION

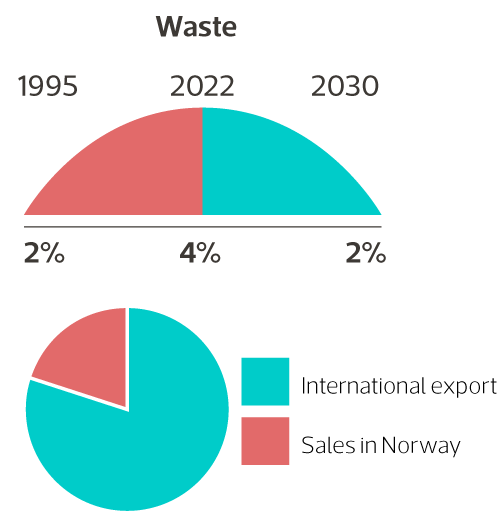

The figures above refer to the factories at Sirevåg and Frei in 2021 – 2023, and do not include the environmental impact of subcontractors and partners.

Sustainability – our gift to future generations

Aleksander, supervisor and safety representative

We want to be open about our impact on the planet, and we are working to make production even more sustainable. We believe that our measures will have the greatest impact in the areas highlighted here:

OPTIMISATION

WHAT WE WANT TO ACHIEVE

WHAT WE HAVE ACHIEVED

INVESTING FOR THE FUTURE

Upgrading the existing factory at Sirevåg

GOAL

A NEW STANDARD FOR SUSTAINABLE INDUSTRY

A new factory is helping to achieve our innovation potential and makes us more competitive on the European market.

MORE AND BETTER FOOD FROM THE INGREDIENTS

The goal is for all raw materials to end up in a process that will create additional value. Unused ingredients have a huge potential.

50% HIGHER PRODUCTION

We will optimise every step from production to processing – and utilise every resource.

ONLY 5% HIGHER use of ENERGY

We have initiated a number of measures to optimise energy use. This will dramatically reduce the energy used per final tin.

5–10 %

MORE STAFF

Modern solutions for production, technology and maintenance will require less manual work – however, we are making plans to provide secure and long-term jobs.

FLEXIBLE

TESTING LINE

We will perform high-quality research and develop knowledge about the use of leftover raw materials; this knowledge can then be used for teaching, application and innovation.

FULLY AUTOMATED WAREHOUSES

The use of robots will significantly increase capacity and ensure better project management.

MORE EFFICIENT DISTRIBUTION

Lower unit costs, more frequent deliveries and a longer shelf life.

FUNDING

RESPONSIBILITY

General manager, Jon

COMPLETED

2024

CONSTRUCTION PROCESS

RESPONSIBILITY

General manager, Jon

COMPLETED

2026

The best place I have ever worked!

Roberta, production worker

OPTIMISATION

Energy

ENERGY-SAVING

MEASURE

Partnership with Nofima

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

Planning stage

ENERGY-SAVING, SIREVÅG

MEASURE

Upgraded factory will reduce energy consumption by 25% per kg finished product

RESPONSIBILITY

General manager, Jon

COMPLETED

2024

ENERGY-SAVING, FREI

MEASURE

Utilisation of warm air during air drying

RESPONSIBILITY

Technical manager, Kai Arild

COMPLETED

2025

Gas

MEASURE

Transition to biogas

RESPONSIBILITY

Technical manager, Otto

COMPLETED

2024

PHOTOVOLTAICS

MEASURE

Photovoltaics on the roof

RESPONSIBILITY

General manager, Jon

COMPLETED

2024

It’s wonderful that we are able to use most of the animal.

Tanita, production worker

OPTIMISATION

Reducing waste

HIGHER PERCENTAGE OF FRESH RAW MATERIALS

MEASURE

Better planning and new reception hall

RESPONSIBILITY

Factory manager, Roy Vidar

COMPLETED

2025

LOGISTICS AND ORDERING

MEASURE

Bigger production runs

RESPONSIBILITY

Logistics- and quality manager, Ingvild

COMPLETED

Ongoing

RAW MATERIALS STORAGE

MEASURE

New automated warehouse

Raw materials will be stored in silos

RESPONSIBILITY

Factory manager, Roy Vidar

COMPLETED

2025-30

REDUCE WASTE MATERIALS IN CLEANING PLANT

MEASURE

Bigger production runs – less waste to be collected / flushed

Product sorting

RESPONSIBILITY

Factory manager, Roy Vidar

COMPLETED

Ongoing

WATER CONSUMPTION

MEASURE

Hot water from autoclave used for flushing/cleaning

Look at possibility of selling surplus heat

RESPONSIBILITY

Technical manager, Otto

COMPLETED

Ongoing

BULK/DEFECTIVE PRODUCTS

MEASURE

Automation of dry goods

RESPONSIBILITY

Factory manager, Roy Vidar

COMPLETED

Ongoing

FACTORY OUTLET

MEASURE

Open factory outlet at Otta as well as Sirevåg

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

2023

OPTIMISATION

Transport

Product transport is optimised around the current system. Nortura’s vehicle energy requirements are described on their website.

INTERNATIONAL

MEASURE

Look at possibility of transporting containers by sea

Biofuel requirement

RESPONSIBILITY

General manager, Jon

COMPLETED

2030

NORWAY

MEASURE

Improve distribution to retail chains

Full incoming vehicles bringing raw materials, and full outgoing vehicles

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

2026

There’s a great working environment here

Bartosz, production worker

AN OPPORTUNITY TO GO GREENER AND MAKE EVEN BETTER USE OF MATERIALS

To achieve our goal of receiving and refining all the leftover materials from the production of food for human consumption, we have started innovation projects in our facilities, as well as projects out in the market.

CONTINUING DEVELOPMENT IN RESEARCH COMMUNITIES

MEASURE

Help to develop protein refining work to maximise efficiency.

Strengthen our own teams and partnerships with others.

Apply for R&D funding

ANSVAR

Factory manager, Roy Vidar

Quality manager, Roswitha

External partners

COMPLETED

Ongoing

SET UP OUR OWN PRODUCT DEVELOPMENT LINE

MEASURE

Make better use of raw materials.

Utilise a wider range of raw materials.

RESPONSIBILITY

General manager, Jon

COMPLETED

2024

NEW OPPORTUNITIES

There are dozens of good-quality raw materials that we make no use of today. For example, we will be looking at cracked eggs from Nortura, more recipes with fish, vegetarian products, and partnerships with prawn trawlers.

ANIMAL FOOD FOR THE FUTURE

The next generation of dog owners will choose sustainability. They want good choices for themselves and their best friend. We will actively look for partners who will join us on the journey from innovation to the food bowl.

FINDING NEW INGREDIENTS

MEASURE

Get customers involved in developing even more sustainable recipes.

Look at more own brands/products with new sources of protein.

Make better use of raw materials that we do not use today.

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

2024

Product development

MEASURE

Continuing development with existing customers.

New partners/customers.

Own brands/ranges.

RESPONSIBILITY

Nortura in partnership with Norsk Dyremat.

COMPLETED

2024

NEW PRODUCT RANGES

MEASURE

Own product (ranges).

Increase sales in Norway.

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

Ongoing

I love working in a place that makes good-quality animal food and takes care of the environment

Toma, production worker

WHAT WE WANT TO ACHIEVE

2022

FOOD SAFETY

Norsk Dyremat AS is certified in accordance with the BRCGS global standard. This is a standard that is based on the newest and most up-to-date food safety standards and methods, and is recognised by the Global Food Safety Initiative – GFSI.

The BRC standard sets strict requirements for the approval of suppliers. All our suppliers – from transport companies, to packaging and dry goods – are approved Approval also covers everything from the origin of the purchased product, and the supplier’s systems for HSE, quality and food safety, to their code of conduct.

Standardised procedures and processes help to reduce waste and ensure that products are of the right quality, and we can demonstrate traceability at every stage.

PURCHASING – USING A SELECT FEW LARGE SUPPLIERS MEANS GOOD RELATIONSHIPS WITH LONG-TERM OPPORTUNITIES

Every year, we buy in NOK 16 million of products and services, so it’s important for us to monitor our suppliers and set requirements regarding their environmental impact.

Our suppliers must address any major environmental impact they may have. They must also look for solutions to improve energy efficiency and minimise energy consumption and climate-related emissions.

CHEMICALS

MEASURE

Reduce the number of different chemicals by 50%

RESPONSIBILITY

Administration manager, Anne Mette

COMPLETED

2024

WASTE MANAGEMENT

MEASURE

Reduce raw materials sent for recirculation / combustion (Biosirk) by 50%

RESPONSIBILITY

Factory manager, Roy Vidar

COMPLETED

2026

TRANSPARENCY ACT / SOCIAL RESPONSIBILITY

MEASURE

Review subcontractors

RESPONSIBILITY

General manager, Jon

COMPLETED

2023

Everyone gets on with each other – and it’s always clean and tidy.

Apichit, production worker

WHAT WE WANT TO ACHIEVE

2022

AN EVEN BETTER PLACE TO WORK

Norsk Dyremat AS shall strive to provide as many permanent and full-time positions as possible for our workers, and good pay and working conditions for our staff. Employee terms and conditions shall be independent of age, gender, orientation and ethnicity. Temporary foreign workers have the same working conditions and pay terms as Norwegian contract workers and staff.

We want to be able to offer more apprenticeships and work placements, and we are an approved training company for logistics and process operator staff. Our staff shall be given the opportunity to get trade certificates. To help our staff to develop more skills, we provide defibrillator courses, first aid courses, HSE 40-hour courses and autoclave courses. By systematically working towards an inclusive working environment, we aim to improve working life for our staff and make our workplace “an even better place to work.”

EASY TO GET TO WORK

Our goal is to reduce car use by encouraging more people to choose to walk, cycle or use public transport to get to work.

Many already choose to walk to work, since they live nearby.

The train station is very close by, and we have cycle parking facilities. If staff need to use their car, there are a few parking spaces and two charging stations for electric cars.

DRIVERS

Good facilities for overnight parking in dedicated area, separate toilets and showers.

GOOD WORKING CONDITIONS AND REPRESENTATION

MEASURE

Employee survey conducted by Nortura

Improve response rate in Cultural Survey from 74% to 84%

RESPONSIBILITY

General manager, Jon

COMPLETED

Every two years

HSE

MEASURE

“Be safe at work” course

HSE 40-hour course

HSE 1-day course

RESPONSIBILITY

Administration manager, Anne Mette

COMPLETED

Ongoing

IMPROVING SKILLS

MEASURE

Two new approved apprenticeships

Autoclave course

Staff exchange schemes – partnerships with research community

RESPONSIBILITY

Administration manager, Anne Mette

COMPLETED

Ongoing

COMPETITIVE PAY AND PENSIONS

MEASURE

Pay and pension benefits on a par with the industry standard

RESPONSIBILITY

General manager, Jon

COMPLETED

Annual

Thinking about the consequences of everything you do – that’s sustainability for me

Roswitha, Quality Manager

It’s fantastic that we can use slaughterhouse waste to make first-class animal food

Tove Anita, production worker

We have a great working environment and wonderful colleagues

Johan, production worker

We look after each other and help each other when we need to

Mergim, production worker

I love being part of the future, taking responsibility

Sander, production worker

It’s great that we use local raw materials in production.

Mats, production worker

I’m so happy here that I never want to leave!

Heidi Anita, , production worker, 21 years with the company

Norwegian raw materials, dried without additives. Quality is cool!

Elena, production worker

Great team spirit in the staff

Hans Bjørnar, production worker

We are good at teamwork. Asking for help is never a problem, we’re all there for each other.

Geir Olav, production worker

PROTECT JOBS AND IMPROVE SKILLS

Equality and diversity

All our employees have equal opportunities and rights. The intention of the Anti-Discrimination Act is to prevent discrimination on the basis of ethnicity, national origin, descent, skin colour, language, religion and beliefs.

We work to promote the intention of the Act within our enterprise. Some of the ways we do this are in recruitment, pay and working conditions, development opportunities and protection against harassment. Norsk Dyremat strives to be a good workplace, where there is no discrimination – where everyone has the same opportunities.

The company employs 62 people: 22 women and 40 men

Updated 31.12.2023

Kvinner

Menn

Permanent employees

22

40

Part-time employees

0

0

Temporary contractors

0

0

Weeks of parental leave

45

35

Pay review

Performed in 2021

Review of involuntary part-time work

Performed in 2023

There are equal numbers of women and men in the company’s management. The board is made up of three men and three women. The 2021 pay review showed that there was no significant difference in pay between women and men performing work of the same value in the same position category. The company is affiliated to Nortura HR and is subject to the same guidelines regarding equality and discrimination and focus on working environment.

Great team spirit in the staff

Hans Bjørnar, production worker

From the very beginning, Norsk Dyremat was founded on the idea of sustainability, and this is still an integral part of everything that we do to this day. We want to share our knowledge about the circular management of proteins for the benefit of customers, partners and society.

ACTIVE USE OF THE REPORT

MEASURE

Communicate our knowledge about sustainability to Nortura, customers and staff

RESPONSIBILITY

Head of marketing, Per Olav

Administration manager, Anne Mette

COMPLETED

2030

Provit

MEASURE

Increase sales in Norway and consider launching elsewhere in the Nordic region

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

2025

HOW DO WE MAKE DOG FOOD?

MEASURE

Tell our story, local roots, use of raw materials (Provit)

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

2024

PARTNERSHIPS WITH THE LOCAL COMMUNITY

MEASURE

A more visible partner in the local community.

RESPONSIBILITY

Head of marketing, Per Olav

COMPLETED

Implemented in 2024, then annually

SPONSORSHIPS

MEASURE

Projects that benefit staff and the local community (around the factories).

RESPONSIBILITY

Logistics- and quality manager, Ingvild

COMPLETED

Implemented in 2024, then annually

CONTACT